A sharpened steel wedge in a block of wood that will, when set up right, pull off gossamer shavings leaving a polished finish straight off the tool. That is where we are going.

I am to take you on a journey. A journey into a way of working with wood that may change the way I shine pieces of furniture. It may work it may not, artists are used to taking this kind of risk, accepting that more than half of our daft ideas are just that, daft ideas. But this time you will be coming with me, I will report periodically on what I have learnt, and share it with you, if its a failure that too I will share.

Way back in the 1970s Japanese tools came, along with James Krenov, into the lives of as many British woodworkers. I picked up, used and reviewed Japanese chisels . What I learned about Japanese tools in 1980 I learned from an American monthly newsletter called “Mahogany Masterpieces” I learnt about the forging process involved in creating a high quality blade. This was a development in Japan comming out of their Samurai sword making history. Super sharp edges that could chop through three bodies at on blow…

What they created for us was a supremely sharp and hard wearing edge. Made of two steels, a hard steel at the cutting edge, with a backing of softer steel. The hard steel itself had been forged. That is, it had been put into a hot forge, made a red and then beaten with a hammer. This forging process not only changes the shape of the steel but it changes its structure. Steel has a structure a little bit like long grain rice. When it is beaten and hammered those long grains come into alignment and form a narrower tighter structure. This is why these edges are capable of becoming sharper, it is because of the forging of the basic usually “blue” or “white” quality steel.

This forged cutting-edge is the laminated to a softer backing steel this is done to make sharpening easier and to make the blade accept shock more readily. The laminating is done in the hot forge and results in the very best cutting edges a woodworker can get hold of.

I have known this for years and benefitted from using great “Ouchi” chisels for the last thirty years. But I never messed about with planes until now. Japanese planes were tricky, there was a mystery to setting them up that was not so easily unravelled in the days before World Wide Web . And, after all we were having enough of a problem setting up western planes. These planes needed very careful setting up, the blade never fitted the body, and the bodies needed to have convex bases to function and you pulled the damn things not pushed them. So why bother?

But these hand planes are sublimely simple and very sophisticated. A sharpened steel wedge in a block of wood that will, when set up right, pull off gossamer shavings leaving a polished finish straight off the tool. That polished surface, that hand made shine, THAT is what I want! Something elemental that cannot be put there with plastic polishes. That, combined with CAD development, a three dimensional printer and a CNC machine will I hope take my furniture to places I have yet to see.

So why are you always on that laptop Carol asks? The truth is that Ebay to a newcomer can become quite a distraction. I have, after hours of research bought an antique Japanese plane iron. I was quite startled when my bid was accepted at £23.30. My bid was £11.00 and my reserve £30.00 and it all happened in the last twenty seconds!! I admit to being no Ebay Warrior but I enjoyed the tussle so much that another Kanna, for that is the proper term for a japanese plane and blade, will be arriving soon. Just dont tell Carol.

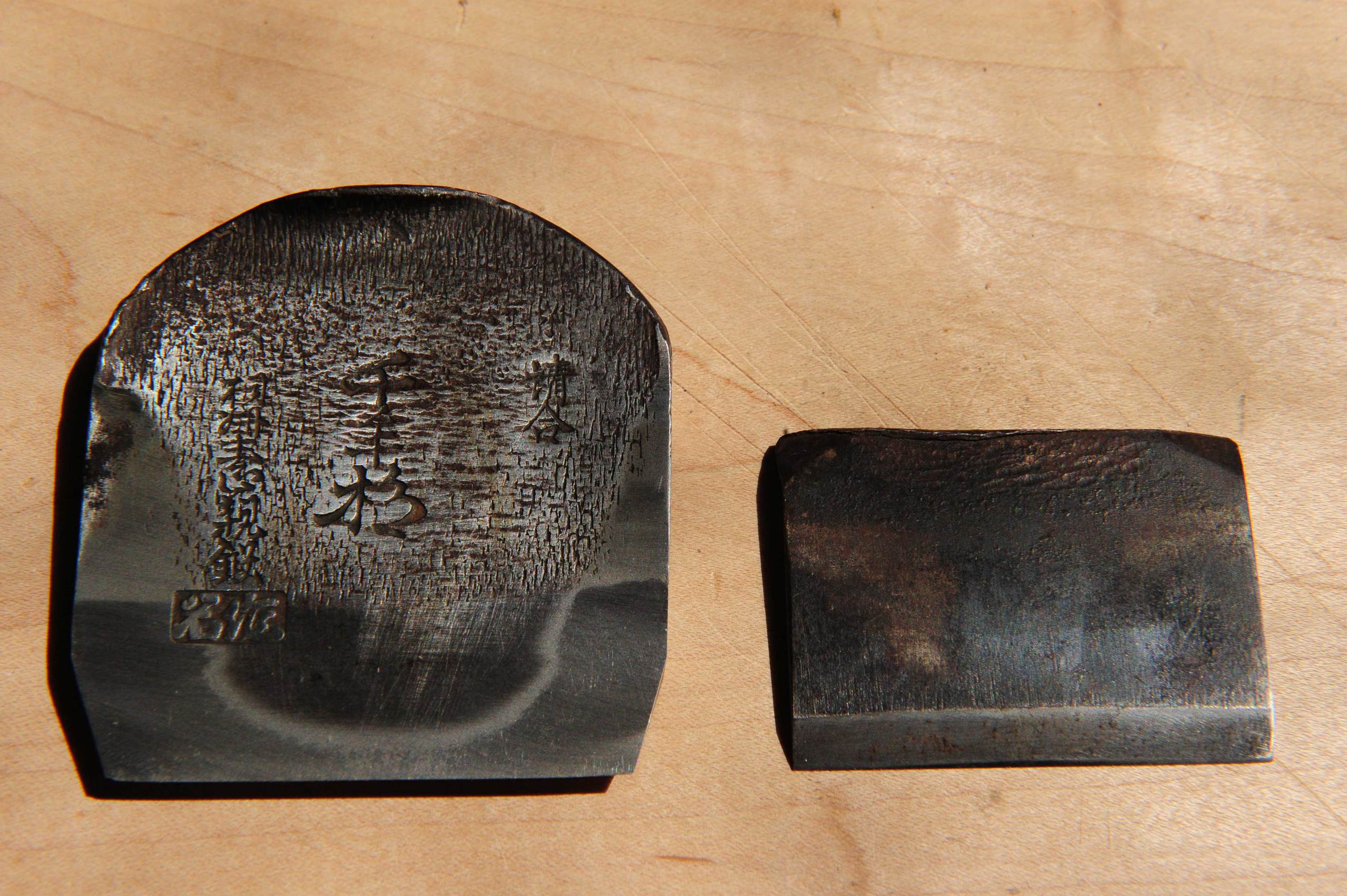

When it arrived I was like a child at Christmas tearing open the package I cant remember getting this excited by tools for over thirty years. I was stunned on opening by how heavy and elemental these two bits of metal were. Clearly a skilled person had invested hours into their existence and other skilled hands had used them perhaps for thirty or forty years. Half the life of the blade was still there and I plan to use what remains of it.

Next I will tell about flattening and restoring this blade to sharpness and finding a body to fit it to. Apparently for each blade there will be ten bodies, all of them dead.

toodle ooo…