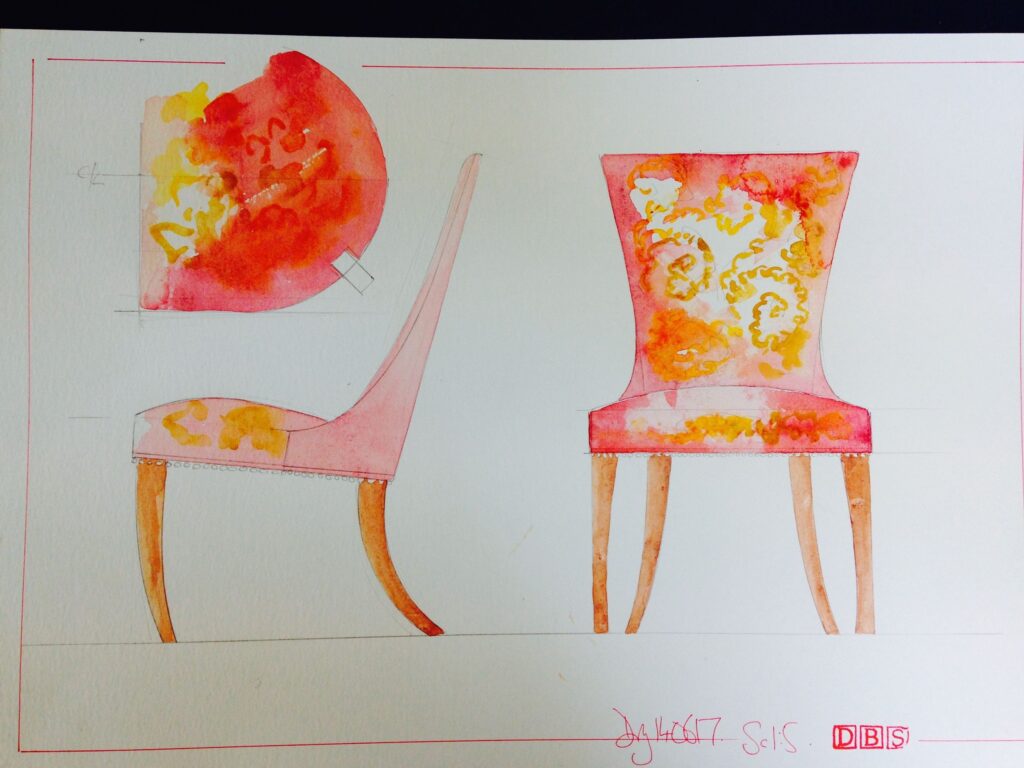

CHAIR MAKING PART 2

The process of making the chair is really, with us now in full force. I give Daren the drawing, he turns it into a rough but accurate full size chair. In the process of doing that, problems emerge. I’m watching the process of these problems emerging like a hawk and trying not to say anything. This is because I usually need a bit of thinking time.

How does that element fit on to this element, giving it enough strength for the junction yet being beautiful and linear and elegant. How can the eye be led down that element and across that form without the Mark One Eyeball being bored to tears. THAT is the designer talking.

But how can Mary pull her fabric around that shape, and how can we make that form, and will it sit well. HELLS BELLS, its got to sit well, as well.

So we start with the ground and build up. Daren will use a flat surface to build the prototype upon. And he will create another surface that will support the seat. This is the first part of the prototyping process. Making the seat, this rests upon what will be a temporary MDF armature.

This puts the seat at the right height to sit upon and maybe puts a slight fall from front to back. This helps you sit back in the chair. Not too high a seat as we don’t want pressure behind the thighs. Not too low or you have trouble standing. No front rails because to stand your heels go back behind the line of the front legs. Then the legs are fitted to the seat. We fit quick and cheap here nothing too fine as they go on and off many times , both front and back legs go on now.

Here we are using a laminate of three sheets of plywood to create this seat. Its faster than playing about bending curved rails. The mail challenge is to overlook its weight which will be reduced when we cut out the centre and the visual weight. Having a back uphostered will balance this shape the fabric which is ornate will also help. SOO……. see beyond what is in front of you.

I want the chair to have the waist of a sensual and curvaceous woman. Rachel, one of the design decorators commented on this and she is absolutely right. When they come to see the prototype, what I am going to try and do is have two prototype chairs there for them to see so they can choose what kind of waistline they want. My job is to give them choices, each of which will work pretty well. The other reason for giving them two choices is to give them a choice of this or that and not something else. If they go for something else we’re into scheduling problems. This whole job has got to go in to a container and be shipped out to Dubai in early February and we’re right on the edge of the schedule right now in late October. So tension is in the air.