I suppose the problem with jigs is that I can’t make up my mind about them. I can’t make up my mind whether I love them or hate them. When I see complex forms being created immaculately under a jigged system, I love them, yet when I see the absence of free workmanship, I hate them. When I see my bank balance, I love them, but when I see the piles of jigs cluttering up my workshop, I hate them.

You know the feeling, don’t you, you design this really clever little jig that solves that tricky little technical problem and you can’t bear to part with it. Hence, it goes under the bench or into the corner or under the stairs or, if you are like Graeme Scott who works with me, you gaily festoon the walls of the workshop with your beautiful jigs. Now, this approach is alright provided your jigs have a future. We have a set of jigs, made about five years ago by Malcolm Vaughan when he was working here, that has earned us well over £100,000 in that short time, but equally, we have hundreds of other jigs that have only been used once.

We have a set of jigs, made about five years ago by Malcolm Vaughan when he was working here, that has earned us well over £100,000 in that short time

Perhaps I should begin at the beginning rather than in the middle.

This ranting about jigs has been provoked by a perfectly valid request that we should have storage space for all these jigs in our new workshop. A “jig storage room” was the proposal and a very sensible proposal it was when you look at the latent value held in a set of good chair making jigs. But I know in my heart that it is a bit like saying let’s have a room to store all our offcuts, all those valuable bits and pieces that we might need some time in the future. In five years, I feel I shall be reporting in “Woodworker” that some poor devil has opened the door of the jig storage room and been killed in an avalanche of unidentifiable miscellaneous pieces of MDF.

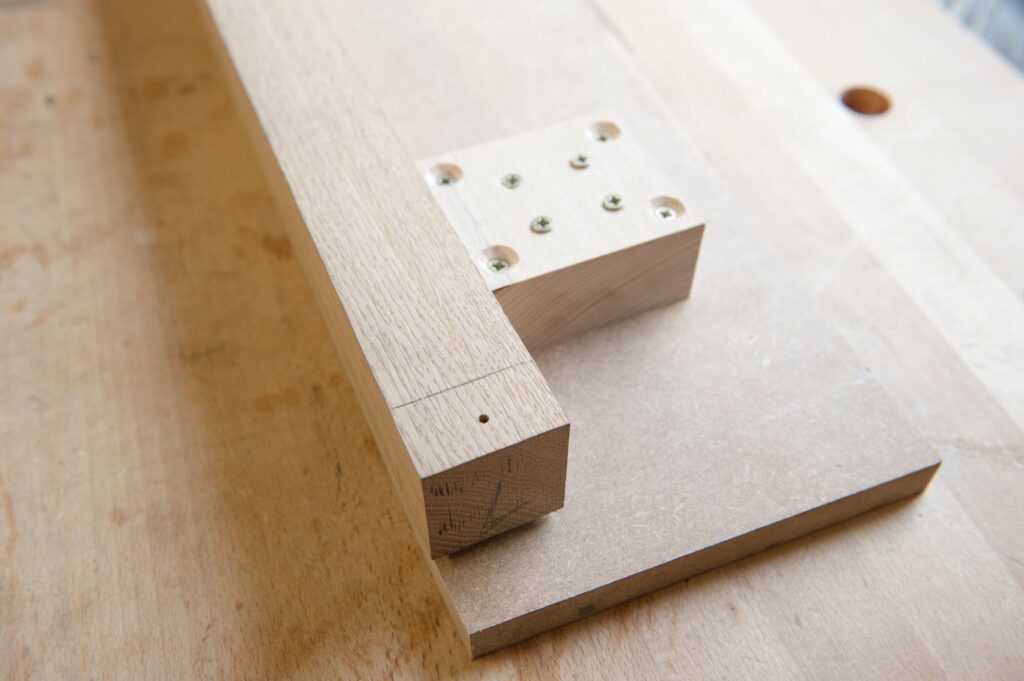

Perhaps a definition of a jig would be useful, and we should begin, like all good definitions, by saying what it is not. A jig is not a template. A jig is not a shaped piece of hardboard or thin plywood that you draw around to get the profile of a chair back leg. Instead, a jig would be used to guide a cutter, usually the cutter of a piece of tooling on a machine, to exactly cut out the shape or profile of that back leg. So a jig is an appliance or fixture that holds a job in a certain attitude to a cutter and guides that cutter through the job. Jigs are not marking out tools but guidance systems, which brings me to my other worry about jigs.

Our forefathers didn’t use jigs; they used templates. They would draw around the back leg, maybe rip saw shy of the line, then finish to the line with a hand plane. We do that all in one operation on a spindle moulder, and we probably do it more accurately than he did and therein lies my concern. For it could be argued that jigs are tools of industry rather than tools of expressive craftsmanship. David Pye, in his famous book The Nature and Art of “Workmanship”, talked of two concepts: “workmanship of risk” and “workmanship of certainty”. “Workmanship of certainty” is the industrial process whereby unskilled machine operators can get the same results from a machine time after time. “Workmanship of risk” gives us, as craftsmen, the responsibility of guiding the cutter through the job by the application of skill and judgement. Now unlike machines, we are prone to making mistakes, doing things slightly differently each time. No doubt David Pye would argue that it is this evidence of skilful human activity that lends the handmade object its presence.

So where does that leave us poor jig makers? By using these machines, by using guidance systems that enable us to create clever and unusual shapes and make difficult joints very accurately, are we robbing ourselves of our birthright? I don’t propose this as a rhetorical question because I genuinely don’t know the answer. I believe that there are situations when jigs must be used, but I believe equally that the purpose of jig making is very seductive and can lead to all the thought and care going into the manufacture of the jig rather than the object.