SHARPENING – THERE’S ALWAYS A CORNER

End of a day spent sat on my backside for six hours working out what’s going on, and what might go on in the next twelve months. If I get this wrong there are quite a few families here that will be affected. So I have a responsibility to get this right.

It’s not that I don’t enjoy doing it, I’m not a natural business person. I’ve learnt to do this. The trouble is sitting at a computer screen in a nice warm room is particularly seductive and getting up and actually doing WORK is not. Unless I have done regular physical work I don’t recall the endorphine rush quite so vividly as the warm feeling of sitting doing nothing.

So I got up and sharpened a Japanese chisel. A big old wide chisel I bought on Ebay. I keep an eye out for tools like this that look like they’ve been properly used by skilled craftsmen. Sometimes I can get them for a price less than I would pay for a new tool. I think this one was about thirty pounds. But then the import tax and postage add up. But I do like using tools that have been handled by somebody else who hopefully knows what they’re doing. This one was however probably used by a moron.

This blade had clearly never been properly prepared and sharpened. The back of the blade was so out of flat that it took me the better part of an hour and half rubbing on a granite stone with one eighty wet and dry abrasive before I got somewhere near flat.

When I’m in that state I quickly switch to a green waterstone which is about three hundred grit. And then move to a one thousand grit which is one of our general sharpening stones. The idea here is that each stage takes out the lines and scratches of the previous stage. So from one thousand grit we go to a Goldstone, a polishing stone, of probably about four thousand or six thousand grit.

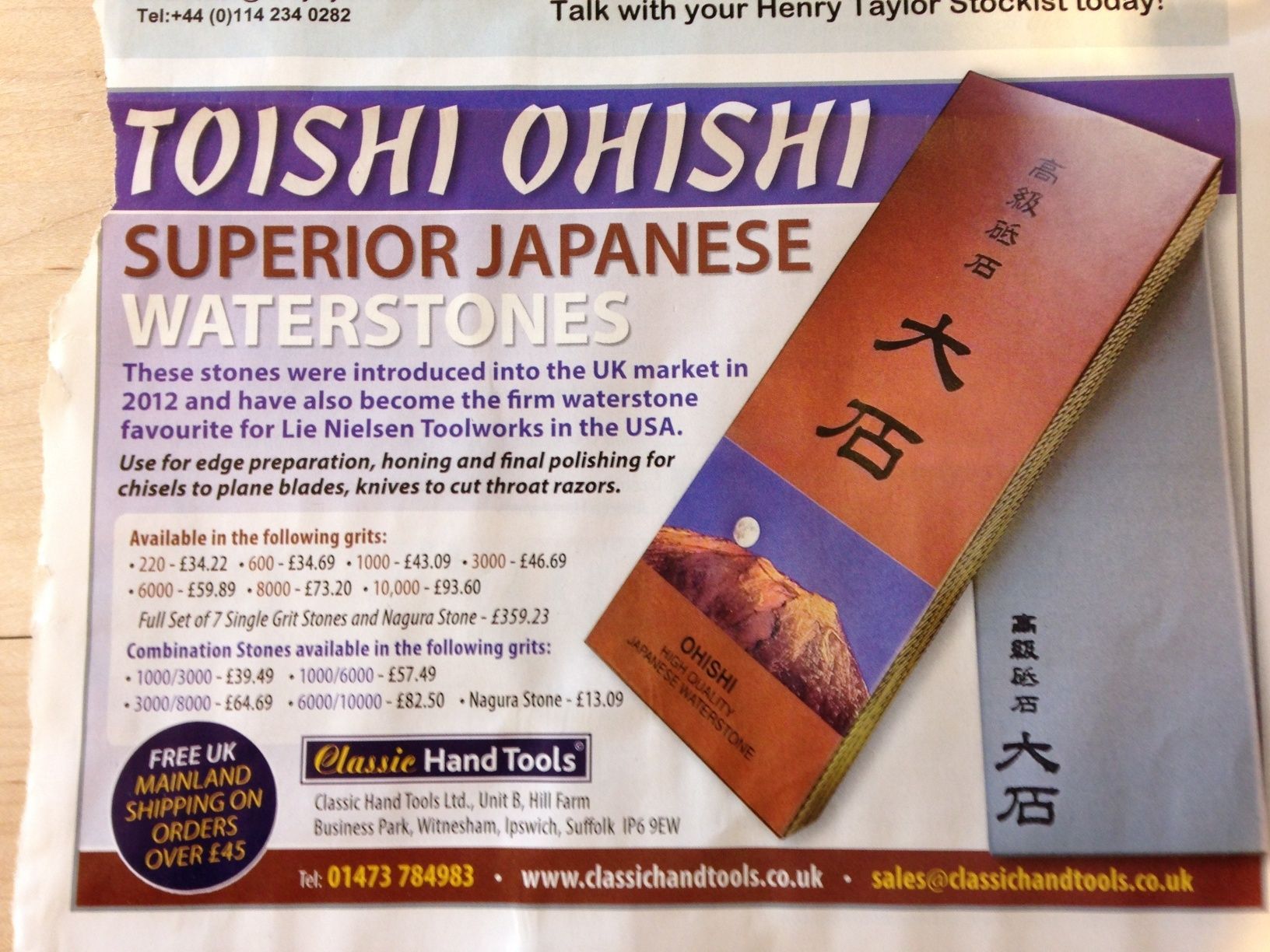

We just started using some new superior Japanese waterstones called “Toishi Ohishi”. These have called from classic hand tools at www.classichandtools.co.uk. They’re a slightly harder stone than we’ve been used to, with stones from Icebear or King, and they last a great deal longer which means in a busy workshop like this where the stones are used all the time we don’t waste as much time as we would do flattening the stones between sessions. Highly recommend it! More expensive than the old stones we had but much better.

I say nearly flat because inevitably there’s a little bit that doesn’t get flattened and it’s always on the corner of the blade. Now pairing and general chisels get a lot of work on the corners. This however is a wide Japanese blade which is going to be used very largely chopping out joinery and creating a straight edge which is where the width of the blade comes in useful. So the corner isn’t going to be the most important part. But still, we should get it flat. I’ve missed it this time but probably next time I’ll have another go at it. Can you see it??