SHARPENING HAND SAWS

I was once told by a very experienced craftsman “You don’t own that saw unless you know how to sharpen it”. I used to watch him sharpen last thing on a Friday night before he’d go home. He’d get a saw out that had had a bit of work that week, clamp it between two bits of wood, sit down, take his glasses off and carefully dress each tooth with one or two strokes of a small saw file. That job done he’d put his hat and glasses on and slip off down to the boozer for a well earned pint.

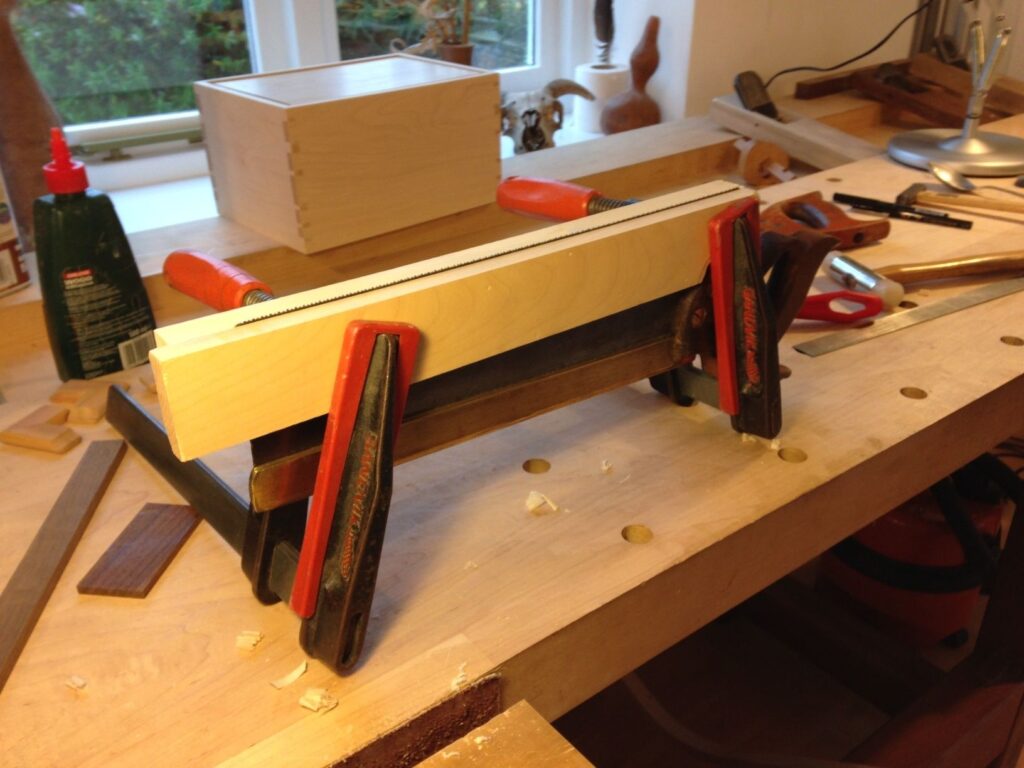

The saw is held with two pieces of wood which are shaped to fit around the handle and allow you to get two or maybe three cramps that sit on the bench and form a stand that brings the tooth line comfortably up nearer to your eyeline.

We avoid all complicated sharpening methods. This workshop only works dry hardwood and most of that work is done ripping. So we only sharpen one way which is at right angles straight across the blade. If we were working with wet soft wood we’d have to do much more complicated work. Dovetail saws have a fine tooth line maybe fifteen or twenty-two teeth per inch. Tenon saws maybe twelve TPI.

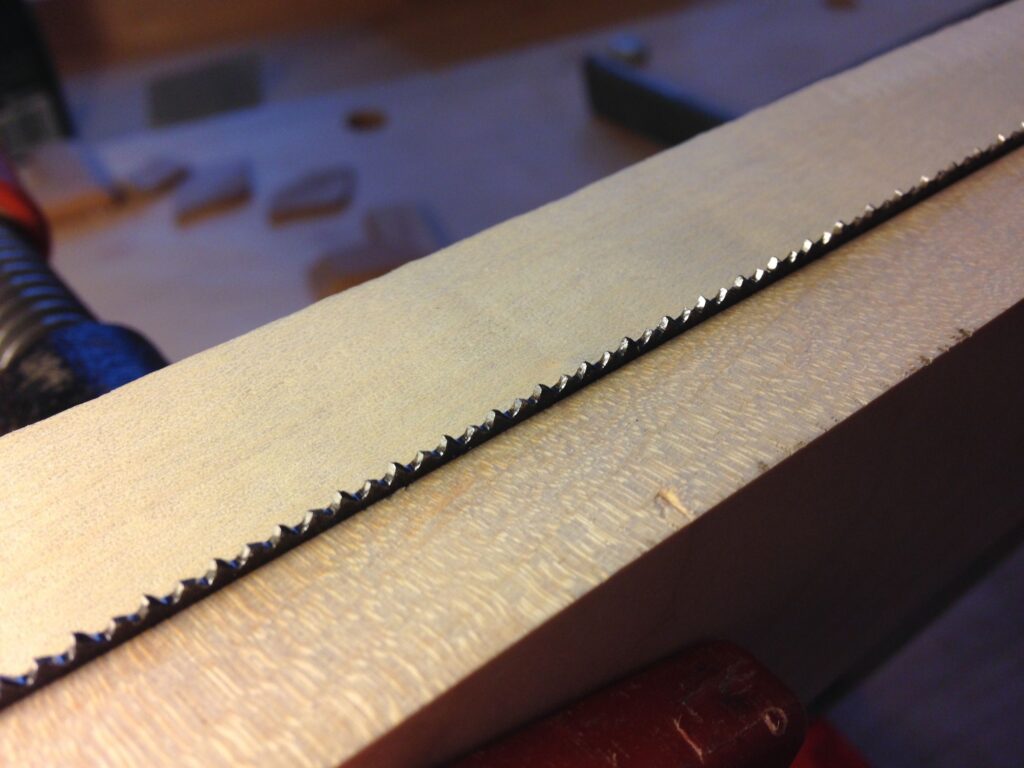

The back of the tooth is almost vertical which suggest that this is a rip saw. As we file the saws that back tends to lay back a little more comfortably which technically I believe makes the saw a “fleam cut” saw. Somewhere halfway between a rip saw and a cross cut saw. This makes the cut smoother and slightly less aggressive.

So, set yourself up, find yourself a stool, put the radio on and concentrate. One or two strokes on each tooth. No more than that. You’re only touching up the saw. The evidence that the saw needed sharpening would be little shiny points at the end of the teeth where they’ve become slightly worn by the wood. No shiny points means a sharp saw. As you file the tooth line becomes shiny and reflective and you can see where you’ve been.

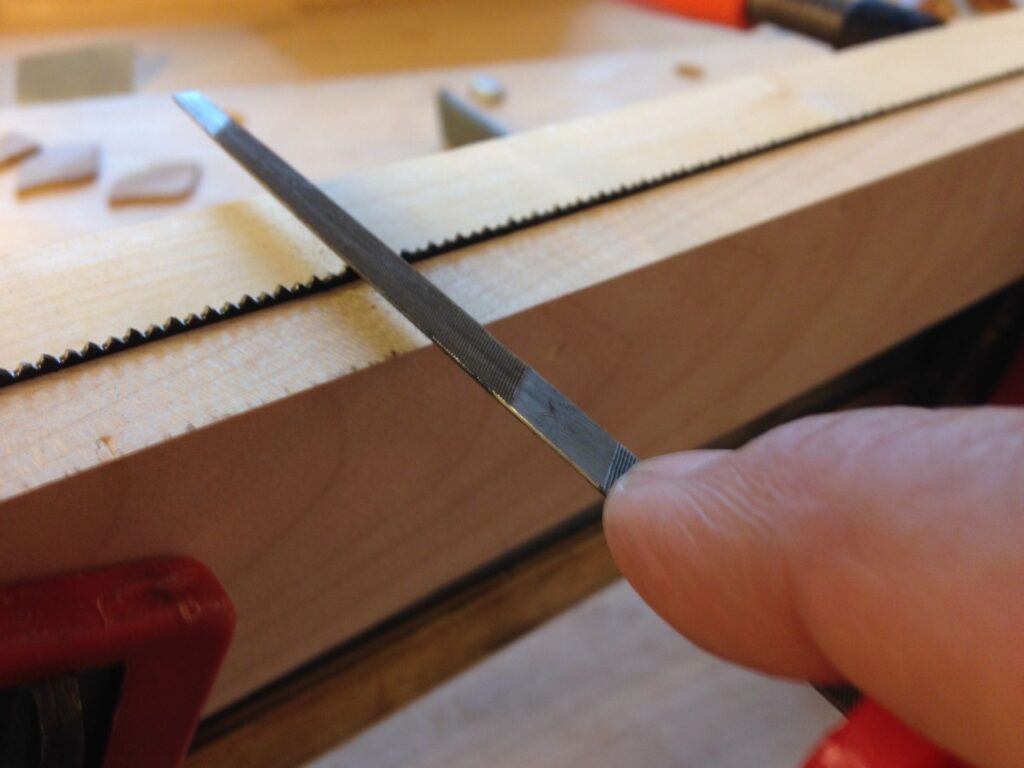

The tool you’re using is the finest triangular saw file you can get. If you want to be ultra careful you can file alternate teeth then turn the saw and file the teeth you’ve just missed. But frankly I don’t bother with that. Filing does leave a slight rag on the side of the tooth line but it usually comes off within a few strokes of the saw.

Keeping saws nice and sharp, really keen, is as important as keeping chisels and plane blades nice and sharp and really keen. Working with a dull saw is hard work, like working with a dull craftsman.